1. Longboard Decks

This page will give you an explanation of the different parts of a longboard, which will help you choose the right components for your setup. We’ve divided the wiki into six chapters, one for each component set of a longboard. Here you’ll learn everything about decks, axles, wheels, and small parts to help you find your way around the world of longboarding.

1.1 General Information

Most longboard decks are made of pressed Canadian maple or bamboo, both of which are often mixed or coated with other materials, such as fibreglass or epoxy. It’s also possible that the board has a core made from these materials. In recent years, materials such as ashwood, poplar and basswood are more frequently used. Though they differ optically from skateboards the segments of a longboard are the same: In the front, there is the Nose, in the back is the Tail, and the space between the mounting holes is called the wheelbase.

1. Deck Width

2. Wheelbase

3. Nose

4. Tail

- Longer Longboards are more stable at high speeds

- Shorter boards are more maneuverable and will perform well throughout the city

Which Longboard is right for you?

It’s difficult to provide general recommendations about how to choose the right lenght and width of a longboard based on your height and weight. While it’s easy to match skateboard decks with your height and shoe size, those parameters aren’t very helpful when it comes to longboard decks. Nevertheless, you can say that the taller and heavier you are, the longer your deck can be. For kids, shorter boards or cruisers might be more appropriate. A good reference point is the wheelbase of a longboard deck. The shorter the wheelbase, the smaller the turn radius when you put pressure on the side of the board. In short, a short wheelbase makes sharp turns possible. Consequently, short riders can have a hard time to controlling a longboard with a large wheelbase because they can be less manoeuvrable. Of course, you can filter for different wheelbases in our shop.

More informative is the longboard flex. There are longboards with and without flex. For example, for carving and cruising, flex can be a nice feature. When you’re blasting down a hill flex is the last thing you want for your board. Generally, you should keep two things in mind:

- Less flex provides stability at high speed

- More flex provides an easy and surfy ride

1.2 Longboard Deck Types

1.2.1 Downhill

In Downhill skateboarding, speeds of 100 km/h and more can be achieved. Most trucks, however, tend to already start wobbling format speeds of about 50 km/h (known as speed-wobbles). Therefore, most downhill boards have a drop so the board sits closer to the ground than other boards, thus preventing the board from wobbling. Here, only the nose and tail are raised, so that the wheelbase is closer to the ground. The pressure points of the rider on the board migrate below the truck turning point, making the board much more stable at higher speeds. Due to the low centre of gravity, taking narrow corners is easier. Dropped decks are typically somewhat slower in steering, which is why many downhill riders choose for flex-free top-mount boards with a high concave – especially on routes with a lot of curves. These boards are often more agile than the dropped boards.

In Downhill skateboarding, speeds of 100 km/h and more can be achieved. Most trucks, however, tend to already start wobbling format speeds of about 50 km/h (known as speed-wobbles). Therefore, most downhill boards have a drop so the board sits closer to the ground than other boards, thus preventing the board from wobbling. Here, only the nose and tail are raised, so that the wheelbase is closer to the ground. The pressure points of the rider on the board migrate below the truck turning point, making the board much more stable at higher speeds. Due to the low centre of gravity, taking narrow corners is easier. Dropped decks are typically somewhat slower in steering, which is why many downhill riders choose for flex-free top-mount boards with a high concave – especially on routes with a lot of curves. These boards are often more agile than the dropped boards.

1.2.2 Freeride

In recent years, Freeride Longboarding established as an extremely popular discipline. Freeride longboarding isn’t necessarily about hitting top speed, but taking advantage of the full width of the road and having the most fun possible when riding down a hill. Therefore, slides and other tricks are hot topics in freeriding. Freeride decks are designed for speed, similar to downhill boards. However, you can also find models with a slight flex.

Most freeride decks are twin-tips (symmetrical), so there is no clearly defined front and rear, which is a great advantage for slides. In addition, most freeride boards are designed as a drop-through board to facilitate sliding and that is why dropped boards often find themselves in the freeride world; because of their deeper position. Some freeride decks, however, do have nose- and tailkicks to make wheelies and shove-its possible.

In recent years, Freeride Longboarding established as an extremely popular discipline. Freeride longboarding isn’t necessarily about hitting top speed, but taking advantage of the full width of the road and having the most fun possible when riding down a hill. Therefore, slides and other tricks are hot topics in freeriding. Freeride decks are designed for speed, similar to downhill boards. However, you can also find models with a slight flex.

Most freeride decks are twin-tips (symmetrical), so there is no clearly defined front and rear, which is a great advantage for slides. In addition, most freeride boards are designed as a drop-through board to facilitate sliding and that is why dropped boards often find themselves in the freeride world; because of their deeper position. Some freeride decks, however, do have nose- and tailkicks to make wheelies and shove-its possible.

1.2.3 Carving

Carving isn’t about reaching the highest possible speed, but rather taking deeper downhill turns. Carving decks are usually somewhat more flexible. In addition, some segments above the wheels are often slightly hollowed out or not even present (cutouts) to prevent the wheels from touching the board (wheelbites) and therefore prevent the consequent horrible sudden stop. Carving decks often have a camber-profile, so the deck is slightly curved upwards, which supports the flex and provides better turn initiation. The layers are pre-tensioned so the deck really “springs” out of carves and gives a very surfy and snowboard-like feeling.

Carving isn’t about reaching the highest possible speed, but rather taking deeper downhill turns. Carving decks are usually somewhat more flexible. In addition, some segments above the wheels are often slightly hollowed out or not even present (cutouts) to prevent the wheels from touching the board (wheelbites) and therefore prevent the consequent horrible sudden stop. Carving decks often have a camber-profile, so the deck is slightly curved upwards, which supports the flex and provides better turn initiation. The layers are pre-tensioned so the deck really “springs” out of carves and gives a very surfy and snowboard-like feeling.

1.2.4 Cruising

Cruising boards or cruisers are actually just extended skateboards, since they usually have a tail and some are also equipped with a nose. Ollies and airs are also possible in a limited context when using this type of deck. But the classic pintail shape remains the most popular shape for cruising boards.

Cruising boards or cruisers are actually just extended skateboards, since they usually have a tail and some are also equipped with a nose. Ollies and airs are also possible in a limited context when using this type of deck. But the classic pintail shape remains the most popular shape for cruising boards.

1.2.5 Slalom

Slalom boards are slightly shortened and typically have a length of 60-90cm, which is why the core scene often discussed whether they should be among the longboards or not. Especially for riders who only occasionally use the board, the slalom board is very popular because of its maneuverability and transport friendly size.

Slalom boards are slightly shortened and typically have a length of 60-90cm, which is why the core scene often discussed whether they should be among the longboards or not. Especially for riders who only occasionally use the board, the slalom board is very popular because of its maneuverability and transport friendly size.

1.2.6 Dancing

As opposed to slalom boards, dancing longboards or simply dancers, are very long since the entire space on the board is used to move on while riding. Additionally, most dancers have kicktails that make some tricks and manuals possible.2. Longboard Trucks

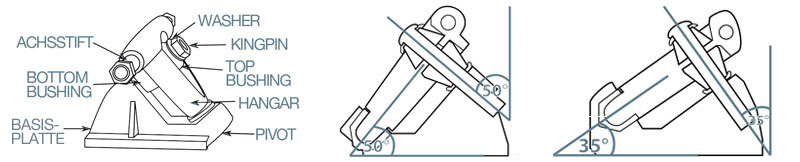

2.1 Construction

Just like common skateboard trucks, longboard trucks consist of a hanger and baseplate which are connected by the kingpin. Inside the hanger, you’ll find the axle where the wheels are placed. The hanger reaches into the baseplate at the lower end – the pivot.

Most longboard trucks have different truck geometry than skateboard trucks. With longboard trucks, the kingpin usually sits diagonally in the truck and points to the outside. Those trucks are called “Reverse Kingpin (RKP) Trucks”. Those are much agiler than the usual “Traditional Kingpin (TKP) Trucks”.

Nevertheless, TKP Trucks are still very popular with retro and cruiser boards due to the close connection to skateboarding. There are also some freeride and downhill longboards that use traditional kingpin trucks due to the low level of the trucks and their inertia. By the way, you can comfortably filter for RKP and TKP trucks in our shop.

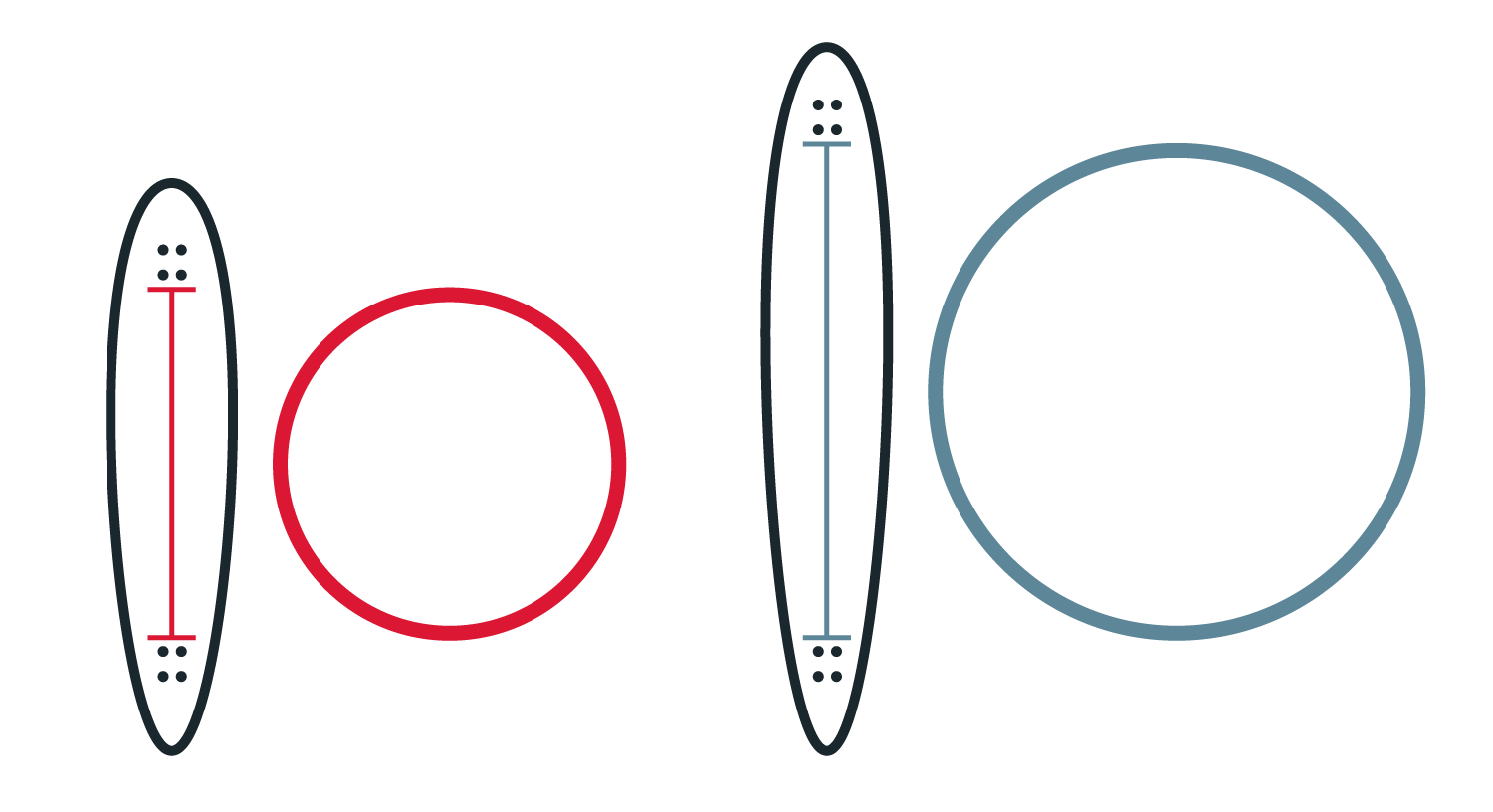

2.2 Hanger Width

When selecting trucks, you should pay attention to the width of your deck. In general, the position of the bearings should align with the outside of your deck. Of course, it is very rare that the trucks will fit exactly to the board. In that case, we would recommend wider trucks than ones that are too narrow. However, it’s your riding style or what you want to do with your setup that determines what trucks suit you best. In the product description of our decks, you can see which truck widths fit best with the longboard decks in our shop.

What are Wheelbites?

When your wheels touch your deck while turning, it’s called a wheelbite. If you’re riding bigger wheels, the distance between them and your deck can be quite short. In this case, unexpected contact between deck and wheels can occur during sharp turns. As a consequence, your board will come to a sudden stop.2.3 Truck Height

The truck height is measured from the bottom of the baseplate to the middle of the axle. While wheel size and the type of mounting affect the height of your longboard, the truck height can directly influence the riding properties of your setup. Generally, you can sum up the differences between high and low trucks as follows:| High Setup | Low Setup |

|---|---|

| More stability at high speed | Surfy riding with deep turns |

| Trucks can be loose / less risk of wheelbites | Trucks should be harder / higher risk of wheelbites |

| Pushing and foot brake are harder | Pushing and foot brake are more comfortable |

| Predictable and controllable slides | Less controllable slides, wheels regain their traction faster |

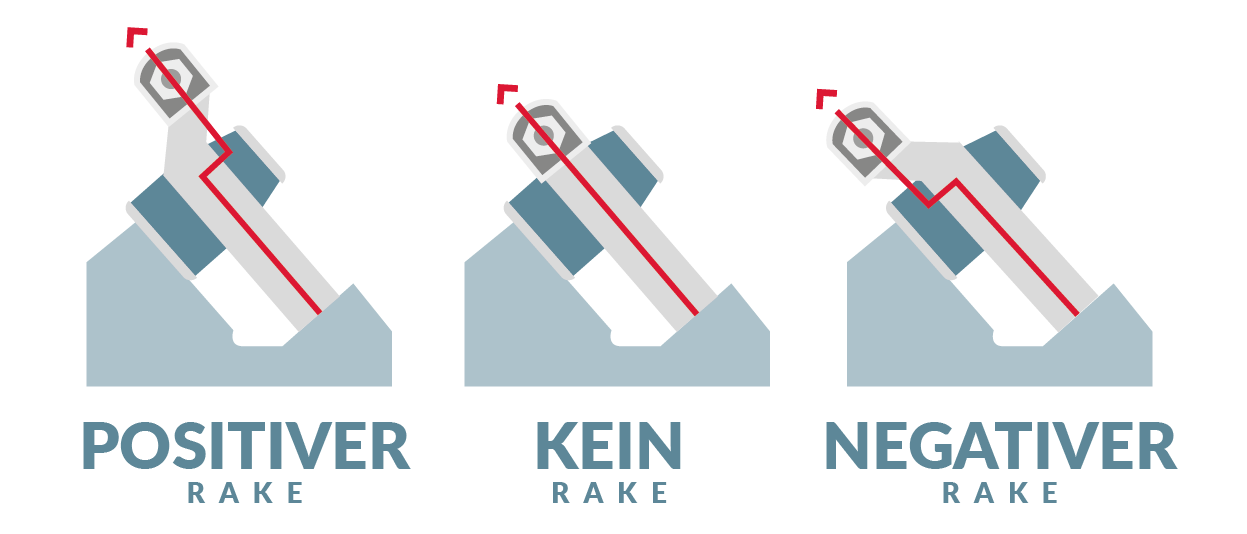

2.4 Hangerflip & Rake

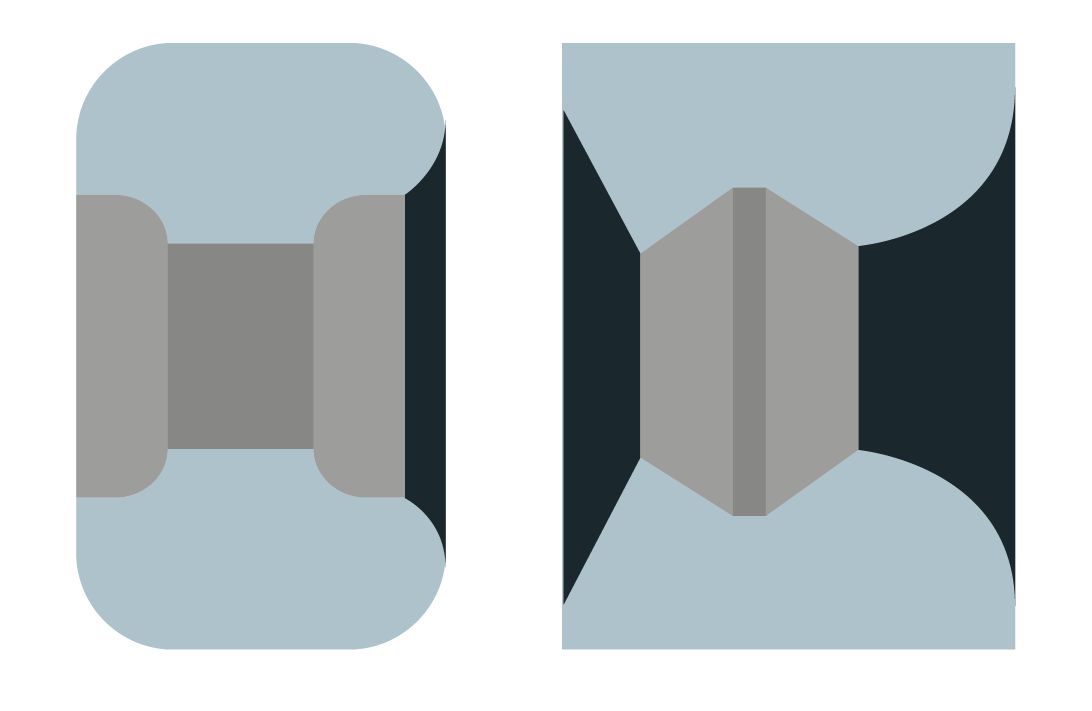

There are some tuning possibilities you can make use of to tailor your truck to your riding – for example in tightening or loosening the kingpin nuts or in giving another bushing type/durometer a try. Another option with some RKP trucks is the hangerflip which changes the trucks’ castor. It requires that the hanger of the truck has rake. A hanger has rake when the axle isn’t on the same level as the pivot but sits slightly offset instead. You could also say that rake changes the position of the wheels in relation to the truck’s axis of rotation. Trucks with positive rake are more manoeuvrable what makes them quite popular in carving and cruising. Sounds super complicated? Agreed, but this graphic should help you understand what trucks with rake look like.

What are speed wobbles?

When your trucks start to wiggle and shake at high speeds and become hard to control, you are experiencing speed wobbles. Speed wobbles can make untrained riders (and professionals as well) slam pretty easily. Therefore, agile trucks and high velocity are an unfavourable combination for beginners. To summarize the facts about rake, you can find the different characteristics of positive and negative rake in the following chart:| Positive Rake | Negative Rake | |

|---|---|---|

| Characteristics | Agile & fast turns | Linear & easily controllable turns |

| Pros | Maneuverable & ideal for carving | Stable & predictable steering |

| Cons | less stable at high velocity | Lazy steering & relatively low setup |

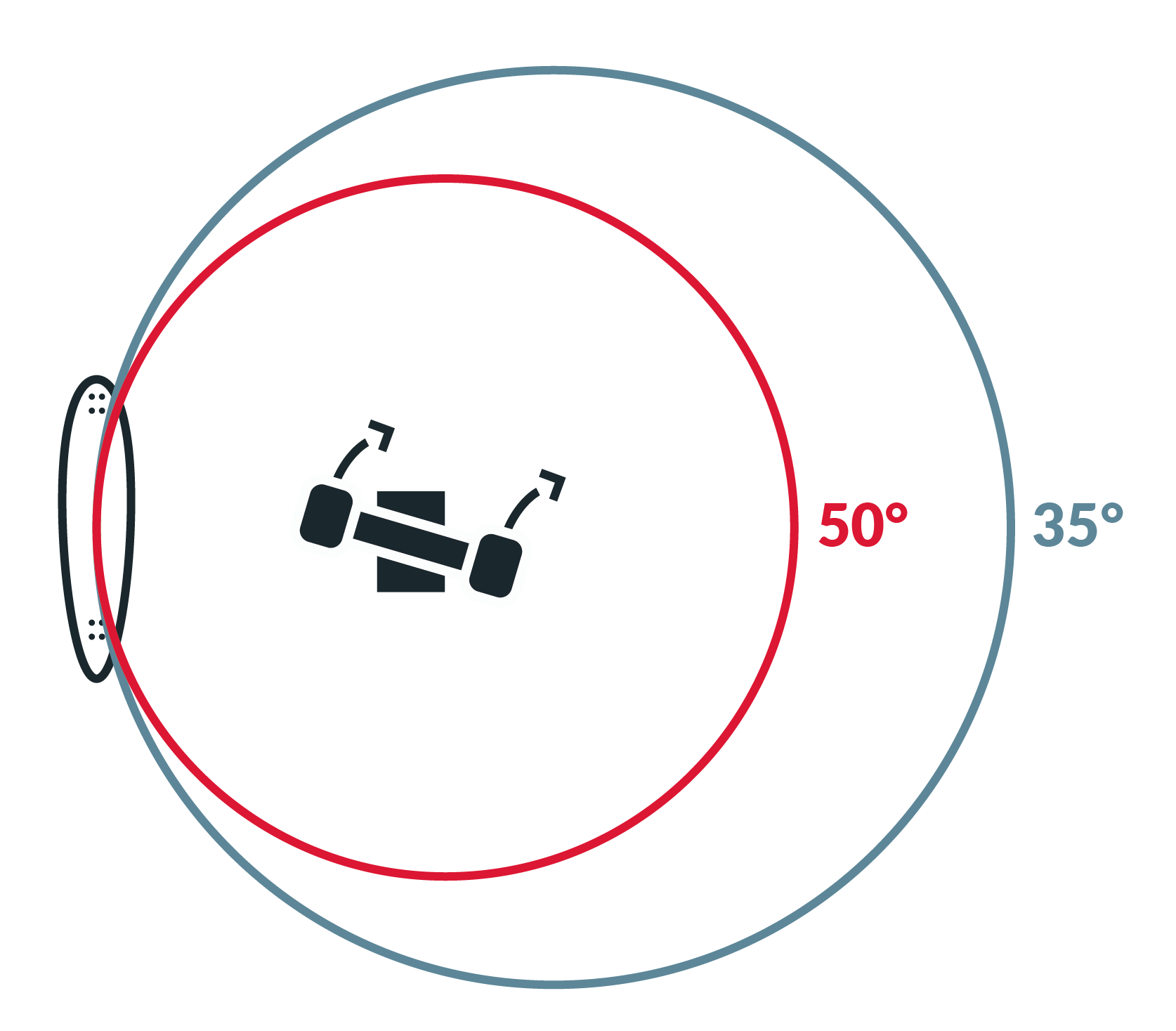

2.5 Baseplate-Pivot Angle

Another important property of RKP trucks is the baseplate-pivot-angle. High angles like 50° for example, make an agile and manoeuvrable truck that is ideal for deep turns and carving. If you like to go downhill with high speed, trucks with a low angle like 42° are what you’re looking for.

Due to the low angle, those trucks are more sluggish but also more stable and easier to control at high velocity. The angle of the truck has an influence on the lean and turn. Learn more about these two in paragraph 2.6.

2.6 Lean & Turn

The last paragraphs should’ve helped you to gain a basic understanding of longboard trucks. Nevertheless, there are some terms you will definitely encounter in the world of longboarding: Turn and Lean.

What is turn?

Obviously, turn describes the radius your longboard goes when you make a turn or, to put it in other terms, the direction your trucks are headed when you’re steering. A general rule of thumb would be that trucks with a high baseplate-pivot angle can do sharp turns, which results in a small radius. When it comes to strong turns, one would say their turn is high. Consequently, trucks with a high angle are maneuverable. Conversely, trucks with a low angle have a small turn, making the radius of the turn bigger and the truck less responsive.

What is lean?

Lean describes the angle your board leans when you apply pressure to the edges of your deck. If the board leans a lot, the lean is obviously high; if it barely leans, the lean is low. To put it in a nutshell, trucks with a low baseplate pivot-angle have more lean. The turn of those trucks is small, so you’ll have to apply a lot of pressure to the deck’s border in order to make a turn. As a matter of fact, with high-angle longboard trucks, it’s simply the other way around.| High baseplate-pivot angle | Low baseplate-pivot angle |

|---|---|

| Less Lean | More Lean |

| Less Turn | More Turn |

| Smaller Turn Radius | Larger Turn Radius |

| Agile & Responsive Steering | Lazy Steering & More Stability |

| Suitable for Carving & Cruising | Suitable for Downhill & Speed |

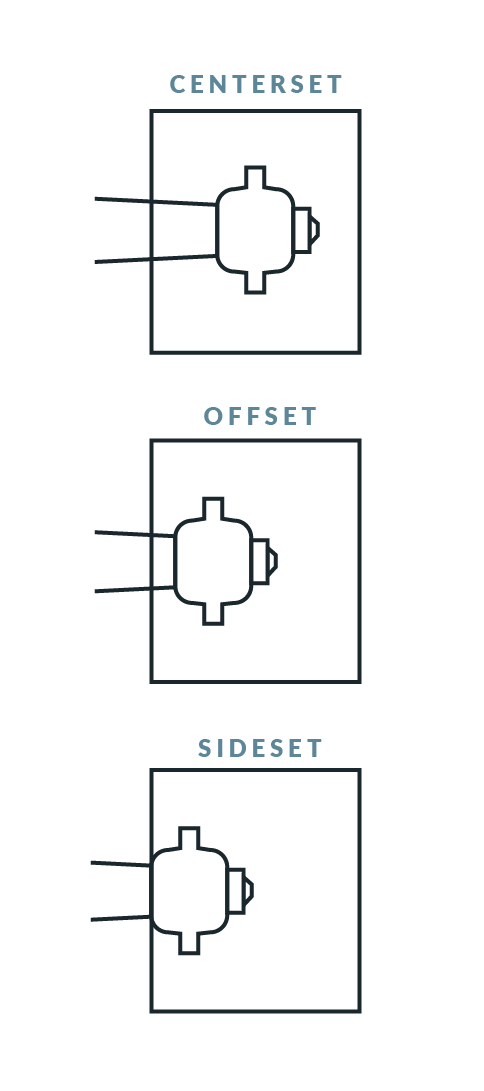

2.7 Assembly

There are basically four different ways to attach trucks to your longboard: Top Mount: The standard installation from below. Drop-Through/Dropmount: With a drop-through or drop mount, the trucks’ baseplates are mounted on top of the board and reach through the deck, which alters the centre of gravity and changes the steering behaviour. Dropped/Lowered: When the longboard deck itself has a drop, it’s called a “Dropped” or “Lowered” setup. These boards have a lower centre of gravity which makes them more stable at high speeds. The truck mounting would technically correspond to “Top Mount“. Doubledrop: A double-drop is the rare combination of “Drop-Through / Drop Mount” and “Dropped / Lowered”.

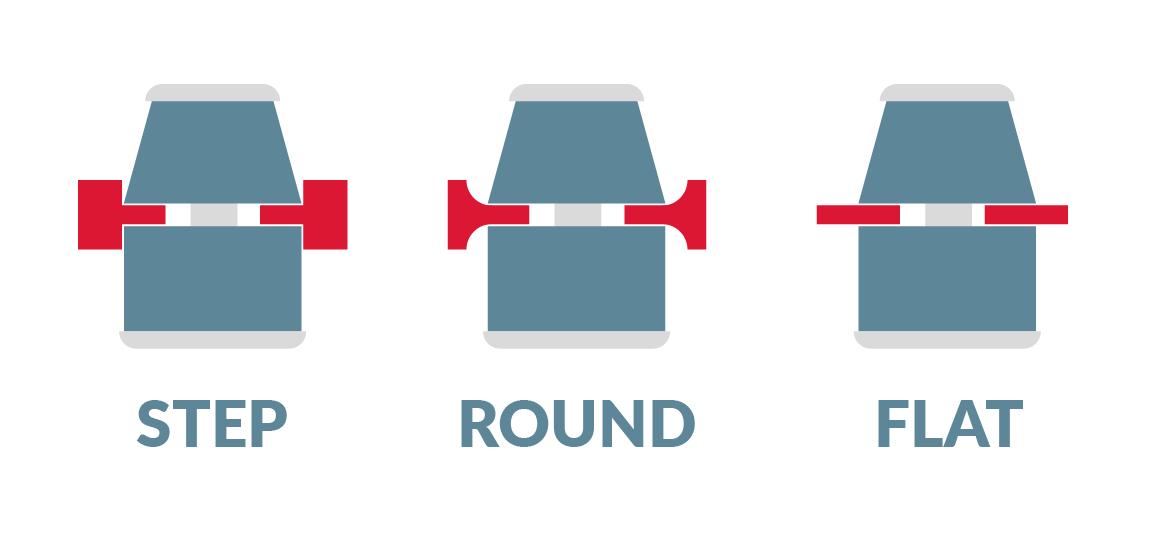

2.8 Bushing Seats

Last but not least, there is one more thing that has an impact on how your trucks perform: the bushing seats. As mentioned before, the bushings sit in the bushing seats of the hanger. There are countless variations of bushing seats but in the end, you can break them down into three different types: stepped, round & flat.- In stepped bushing seats, the bushings sit really tightly, which results in stable steering

- Round bushing seats give the bushings a little bit more room and provide you with agile steering. Ideal for carving and turns

- Flat bushing seats are the most simple but also the most versatile seats. With these, you can experiment a lot with different bushing types. However, they also are less stable at high speeds

3. Bushings

Bushings are the round rubbers inside the trucks. Normally, one top and one bottom bushing are required for each truck, though this is not always obligatory. Bushings are available in different degrees of hardness and influence the steering behavior of the truck. Of course, soft bushings make a more maneuverable truck than hard bushings. The hardness is measured in durometers with the unit A. High A-values like 100A signify hard bushings and low values indicate soft bushings respectively. There are also different forms or types of bushings. Conical (Cone) bushings offer you more manoeuvrability. Flat bushings (Barrel) make the truck more sluggish but also more stable. In addition, there are Eliminator (Double Stepped Barrel) and Chubby (Stepped Cone/Barrel) bushings that block the truck at a certain point, which can be beneficial for Freeriding and Downhill.

1. Cone

2. Tall

3. Barrel

4. Stepped Cone

5. Double Stepped Barrel

| Top | Bottom | |

|---|---|---|

| Cruising | Cone Bushings | Cone Bushings |

| Carving | Cone Bushings | Cone Bushings or Barrel Bushings |

| Freeride | Barrel Bushings or Cone Bushings | Barrel Bushings |

| Downhill | Barrel Bushings | Barrel Bushings or Stepped/Double Stepped Bushings |

4. Longboard Wheels

Longboard wheels are made of polyurethane and have different diameters, widths and degrees of hardness. When choosing wheels, you always have to make certain compromises in terms of grip, traction, slide-ability and smoothness. Here we explain everything you need to know to help you find the most suitable wheels for your setup. If you already know which wheels are the right ones for you, you can filter in our shop for wheel diameter, durometer, hub or simply which terrain they’re designed for (“usable for”).

4.1 Size

When talking about wheel sizes, one is usually referring to the diameter. As you might have guessed, the diameter of the wheels affects the riding behaviour: smaller wheels have better acceleration and braking can be just as easy, but they are not the smoothest of the bunch and the bearings heat up faster. Furthermore, they have better slide-ability but they lose their terminal velocity pretty fast in comparison to wheels with a big diameter. Large wheels remain stable at high speeds and the bearings heat up less quickly. On the other hand, they accelerate slower but keep their terminal velocity longer. When choosing the wheel diameter, you should also take the height of your board into consideration. Combining large wheels with a low setup (Dropped/Lowered), trucks with a low baseplate-pivot-angle and a deck without cut-outs you’re very likely to face some serious wheelbite-issues. If you insist on riding that kind of setup, you can also use riser pads to solve this problem.

4.2 Durometer

As with the bushings, the degree of hardness of longboard wheels is measured in durometers with the value A. Hard wheels have high A-values whereas soft wheels have low A-values. Soft wheels are grippier but tend to slide uncontrollably as they constantly try to regain traction. They also wear out faster because the friction between the road and wheels is higher, which makes them a little bit slower than harder wheels.

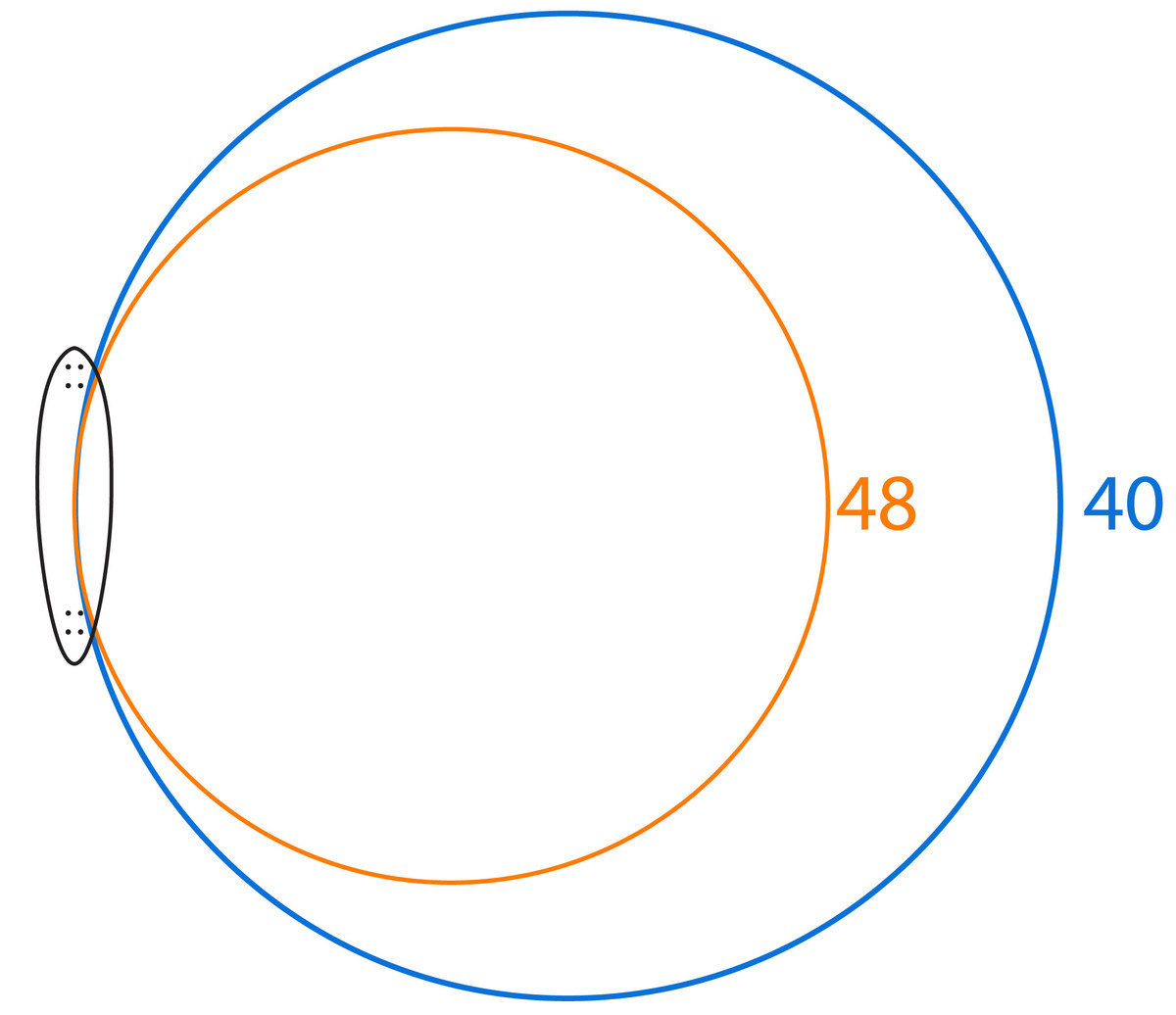

4.3 Hub & Bearing Seat

4.4 Wheel Lip

One more thing that affects the performance of your setup is the lip of your wheels. This means the outer edge of the wheel. Especially during slides, you can feel the difference between various lip types. Sharp and square (angular) lips are grippy since they have a wider contact patch. When you’re doing sharp turns with those wheels, i.e. during carving, you have a lot of traction and the wheel won’t break out into a slide that easily. With round/rounded lips, it’s just the opposite. Here, you’ll have less contact with the ground, which lets the wheels break out and slide easier.

5.1 Bearings

For your longboard, you can just use normal skateboard bearings. You should, however, make sure that the bearings are of good quality to ensure high durability. Bearings are nothing to be stingy about when it comes to longboarding. Ceramic bearings are especially recommended due to their high heat and water resistance.

5.2 Riser pads & Shock pads

1. Standard Shock pad / Riser pad

2. Angled Riser pad

5.3 Nuts & Bolts

| Height shock- / riser pads | ||||||

|---|---|---|---|---|---|---|

| Deck Thickness | none | 1/16″ | 1/8″ | 1/4″ | 3/8″ | 1/2″ |

| 1 – 1,25cm | 7/8″ | 1″ | 1″ | 1 1/8″ | 1 1/4″ | 1 1/2″ |

| 1,25 – 1,55cm | 1″ | 1 1/8″ | 1 1/8″ | 1 1/4″ | 1 1/2″ | 1 1/2″ |

| 1,55 – 1,9cm | 1 1/8″ | 1 1/4″ | 1 1/4″ | 1 1/2″ | 1 1/2″ | 2″ |

| 1,9 – 2,2cm | 1 1/4″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 2″ | 2″ |

6. Griptape

Longboard completes are often sold with the griptape already attached to them. If this isn’t the case or if you want to match your setup to your style of riding, there are different kinds of griptape with different degrees of roughness (granulation) and in various colours. Griptape has a sticky, self-adhesive bottom so you can attach it to your board easily. Protruding residue is simply cut off with a utility knife (cutter). Next to pre-cut griptape for special boards from some manufacturers, you can spare yourself the trouble of griptape cutting with spray-on griptape. Rough and coarse griptape is suitable for downhill setups or if you slide a lot because they provide the most traction for your feet. If you want to do tricks like Ollies on your longboard or if you’re into dancing on your setup, we would recommend a smoother griptape to save your shoes a little bit. Tip: You can use the “Griptape-roughness” filter in our shop to easily find the right griptape for your setup.If you’re completely new to longboarding or if you don’t want to build a custom setup, then pre-assembled complete longboards are the solution for you.

Of course, if you have any more questions, don’t hesitate to contact our costumer service. We’re happy to help you any time!